3K Wind turbine

Download:

Please click the link below to download our 3kW PDF brochure and keep it handy.

1. SCF Supercritical generator

1. SCF Supercritical generator

Wind generator adopts SCF supercritical technology which won a gold award in the 37th Salon Eureka in Brussels. This technology makes real that the weight and size of hummer 3kW generator are one-third of the traditional one, and the generator efficiency is improved from 0.22 ~ 0.28 to 0.4. This ensures that the generator functions perfectly in small wind condition.

2. SKF bearings

2. SKF bearings

Wind turbine adopts two SKF (Svenska Kullager Fabriken) bearings which are produced by the largest bearing manufacturer in the world, with the perfect internal geometric structure, known for its life-time endurance and reliable quality. Ordinary bearings need to be changed every two or three years, while SKF bearings can greatly reduce the maintenance costs on this matter.

3. PLC integrated with Siemens module

3. PLC integrated with Siemens module

Wind turbine’s controlling system adopts the smart touch-screen PLC (Programmable Logic Controller) which is integrated with Siemens controlling unit. The PLC will alarm and adjust the abnormal running status of the wind turbine automatically both timely and efficiently. Siemens module offers high reliability to our PLC and its customers worldwide can testify for that.

4. Low noise

4. Low noise

The design of the rotor blade of Hummer wind turbine absorbs the

highlights of the small aircraft’s airfoil, which is compliance with the

aerodynamic standards. It provides a more aesthetic look and a higher

efficiency and reduces the noise production as much as possible. 5. Triple braking protection

5. Triple braking protection

Wind turbine generally adopts the yawing system and the

electromagnetic braking system to regulate the rotation of the wind

turbine. Besides, customer can order the hydraulic braking system as

well as a third protection. It is easy and convenient to shut down the

whole system both manually and automatically.

Specifications:

Rated power (W) 3000Curve:

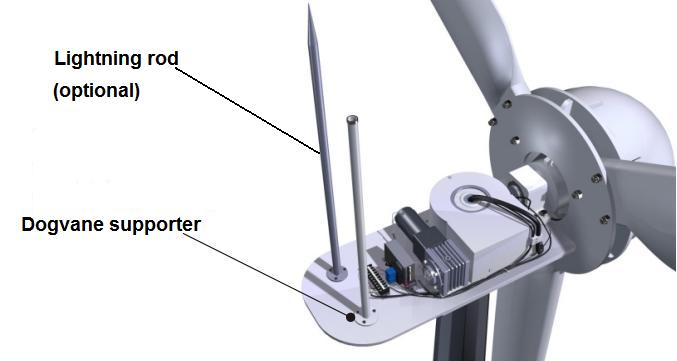

Structure and component parts:

1. Generator Part

It is composed of the patented SCF generator, the nose cone, and the protection cover. Hummer adopts the state-of-the-art SCF supercritcial generator, which is installed in the hub, easy to radiate heat and reduce wind resistance. Made of high-efficiency magnetic materials, special copper alloy, high-strenghth stainless steel and aeronautic aluminum alloys, which is extremely light in weight and small in size, but with higer power producing efficicency.

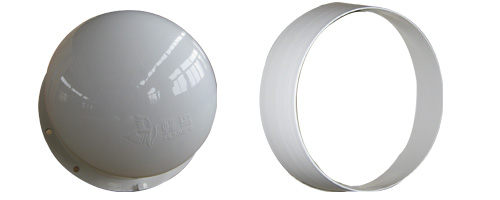

2. Nose Cone & Protection Cover

Both of them are made of the reinforced aluminum alloy. Nose cone is fixed in front of the rotor blades to reduce the wind resistance and radiate the heat produced by the generator. While the protection cover between the rotor blades and the nose cone to provide extra protection to the generator.

3. SKF Bearings

Two SKF bearings ensure the reliability the longevity of our generator. Wide temperature ranges: operation in the high temperature (150-350ºC). Long life span, reach up to 60000-100000 hours. User may not change the bearing during the wind turbine using. It can greatly reduce the maintenance costs.

4. Flange & Blades

The flange is made of fine steel, used to fix the blades to the rotor. The blades are made of glass reinforced plastic, efficiently turn the wind energy into the mechanical energy. Every set of the three blades has passed the strict balance test before the shipping. It is important to fix the blades together which belongs to one set to the flange and never mix them up with other blades which belongs to another wind turbine.

5. Yaw Shaft

It is made of fine steel and used to connect the generator and the blades to the tower. Powered with a 24V motor and integrated with a gear box, which are able to regulate the direction of the generator.

6. Dogvane & Anemometer

They receive the signals of the wind direction and the wind speed.

The dogvane reads the average value of the wind direction every 120 seconds. If the angle between the dogvane and the wind generator axis depasses 10°, the 24V motor will drive the yaw shaft to turn and follow the wind direction automatically.

The anemometer mesures the realtime wind speed. If the wind blows non-stop over 3m/s during 20 seconds, the automactic wind tracking program will start to make the rotor blades surface face the wind correctly; if the wind speed drops below 3m/s, the tracking program will turn to stand-by.

7. Off-grid Inverter & On-grid Inverter

Off-grid inverter adopts SPWM (Sinusoidal Pulse Width Modulation) technology, is able to invert DC with higer efficiency into AC with stable frequency and voltage, filters the noise as well. It is used in the off-grid power system.

On-grid inverter adopts MPPT (Maximum Power Point Tracking) technology and IGBT (Insulated Gate Bipolar Transistor), is able to invert DC with a high power producing capacity and a wider AC voltage output range. It connects to the public grid and there is no need for any power storage device.

8. Siemens Module PLC

PLC (Programmable Logic Controller) adopts the Siemens controlling module and is equiped with a touch screen. It can alarm and adjust the abnormal running status of the wind turbine automatically. Siemens module offers high reliability to our PLC and its customers worldwide can testify for that. It easy to control and operate your wind turbine via our PLC easily and efficiently.

9. Rectifier/Dump Load Controller & Dump Load Box

The controller controls the process of which the alternative current produced by wind turbine into direct current and eventually charges the battery bank with DC. It also controls the switching on and off of the dump load to protect the system against the risk of being overloaded with too much power.

Metal box design of the dump load radiates the heat of the resistance inside quickly via the air convection. So there is no need for an extra fan.